HOW FREIGHT TRAINS MOVE KEY FACTS

- Dispatch centers coordinate train movements and traffic in real time.

- Crews, sensors, and PTC support safe train assembly, inspection, and monitoring.

- Railroads communicate with customers and adapt quickly to keep freight moving

Freight railroads move everything from raw materials like coal, grain, and chemicals to finished goods, vehicles, and consumer products—supporting nearly every sector of the economy. Shipments move as individual carloads or intermodal containers that connect seamlessly with trucks and ships. Traffic levels shift with consumer demand, manufacturing trends, global trade, and weather.

To keep goods moving safely and reliably, railroads operate a tightly coordinated physical and digital system—spanning dispatch, traffic control, train assembly, inspections, and real-time monitoring. Since trains can’t steer or stop quickly, this layered approach to safety is essential. Railroads also work closely with customers to provide real-time updates, flexible service, and responsive logistics from origin to destination.

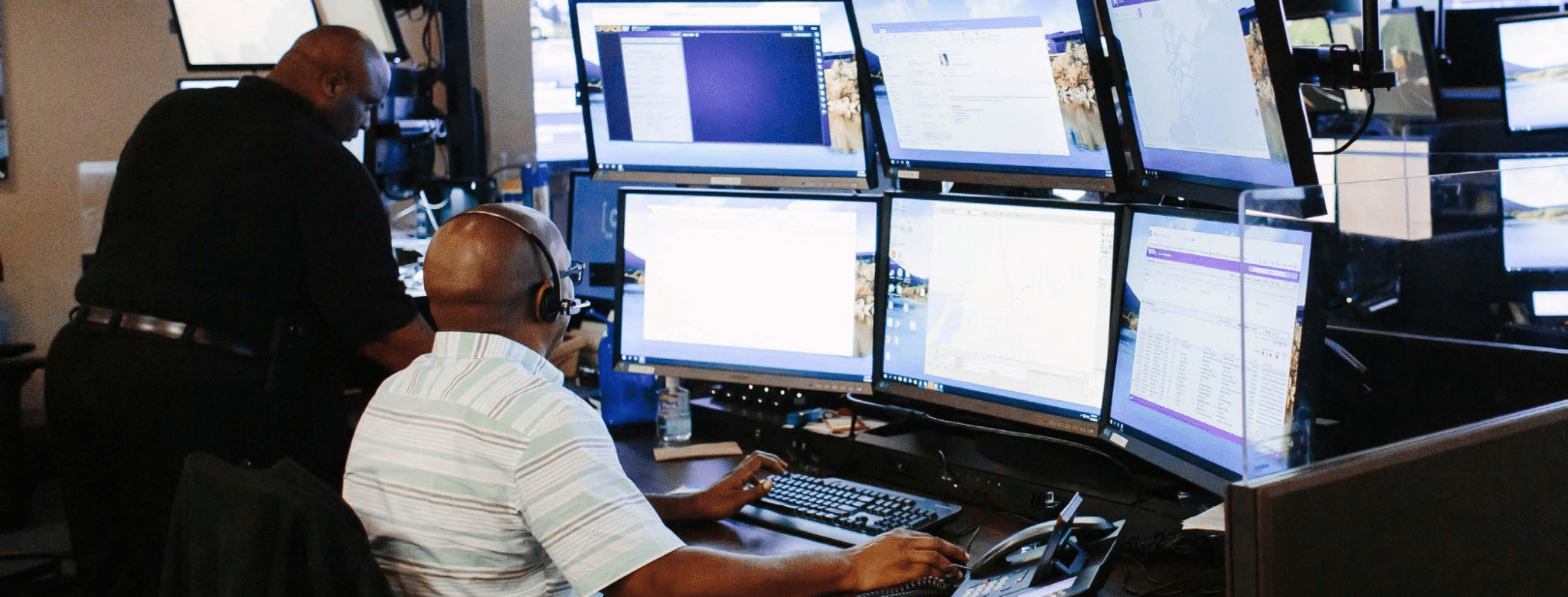

The Dispatch Center

Think of the dispatch center as the railroad’s air traffic control where trained dispatchers monitor and direct train movements across thousands of miles of track in real time. Dispatchers make split-second decisions to optimize train flow, avoid congestion, and respond to unexpected events like weather or equipment issues. They use advanced software, GPS data, and radio communication to manage train routing, scheduling, track occupancy, and coordination with rail yards and other carriers as well as manage rail traffic using signals and power switches.

Train Assembly & Inspection

Before a train departs, employees assemble and thoroughly inspect it. They organize and connect individual railcars in a specific order to form a complete train for a particular route or shipment—a process called train assembling. This work happens in rail yards, where employees sort railcars into a consist, the lineup of locomotives and cars headed for a specific route. Train types include:

- Manifest trains carry a mix of goods.

- Unit trains carry one type of commodity (like coal or grain).

- Intermodal trains carry truck trailers or shipping containers.

Once the consist is ready, qualified personnel conduct comprehensive safety inspections. If anything doesn’t pass inspection, employees remove the train from the lineup and send it for repairs. Safety checks don’t end there—inspections also happen along the route with the help of wayside detectors and acoustic sensors. These inspections cover brake systems, couplers and air hoses, wheels and bearings, car integrity and cargo securement.

Train Operations

Once crews fully assemble, inspect, and clear a train for departure, they turn it over to a certified crew. The engineer operates the train by controlling speed, power, and braking, while the conductor oversees cargo documentation, safety checks, and communication. The train begins its journey at origination and ends at termination. Throughout the trip, crews perform in-transit inspections to ensure safe operations. If they detect a potential issue, they stop the train for closer examination.

Traffic Management

Trains rely on centrally managed systems to stay safe and efficient. Systems control traffic and allow multiple trains to operate safely across thousands of miles of track—many shared by different carriers.

These systems include:

- Centralized Traffic Control (CTC): Allows dispatchers to manage train movements and signal systems remotely.

- Positive Train Control (PTC): A high-tech safety overlay that supports the engineer and prevents collisions, derailments from excessive speed, and unauthorized train movements. PTC also shows the position of grades, upcoming speed restrictions and more.

- Block Signaling: Breaks the rail network into segments to ensure only one train occupies a section at a time.

Ongoing Customer Communication & Managing Disruptions

Freight railroads work closely with their customers throughout a train’s journey to ensure timely, efficient, and secure delivery. This coordination includes real-time tracking updates, scheduling adjustments, and communication about cargo status or potential delays. Railroads also collaborate on loading and unloading logistics, helping customers plan around train arrivals so they can keep their supply chains running smoothly.

Despite extensive planning, delays happen—from weather to external disruptions. Redundancy, flexibility, and strong coordination between carriers help ensure freight keeps moving. When disruptions do happen:

- Dispatchers reroute traffic or adjust schedules in real time.

- Maintenance crews deploy to fix track or equipment.

- Railroads may swap out crews to comply with rest rules.

- Railroads may temporarily share tracks or reroute across partner networks.