Below is the latest edition of The Signal—our biweekly newsletter delivering freight rail news, insights, and interesting facts. Enjoying it? Subscribe to get the email sent straight to your inbox every other week.

January 26, 2026. Edition #186. ALL ABOARD THE BLIZZARD BUS

Well, it’s a bit cold here in the nation’s capital. That makes it the perfect time to look at how freight railroads prepare for winter and keep the network moving safely, even in the toughest conditions.

Stay safe and warm.

—The Signal Editors

Safeguarding Employees & Customers

Winter weather is one of the toughest challenges freight rail employees face. To keep people safe and operations moving, railroads provide specialized cold-weather gear, safe transportation like “blizzard buses,” and extensive winter training.

Freight railroads also provide guidance to help customers keep their facilities safe for rail crews to come in to provide service during winter weather. 👆The video above is one example.

From Blizzard to Breakthrough

👆 A woman shovels the snow away from her car on Jan. 3, 1999, in front of her suburban Chicago home. Copyright The Chicago Tribune.

A single blizzard helped change how railroads operate in Chicago, the nation’s busiest rail hub, where nearly a quarter of all U.S. freight rail traffic intersects with passenger and commuter rail lines. In 1999, what was then the second-worst snowstorm of the century buried the region, crippling rail traffic and exposing the need for better coordination.

That disruption ultimately led to years of close collaboration to create the Chicago Integrated Rail Operations Center (CIROC) in 2015. Today, CIROC operates as a 24/7 regional nerve center, using real-time data and shared dashboards to give railroads a common view of network conditions. When the most severe weather is expected, some traffic may be redirected through other routes to keep traffic fluid.

BONUS👇

In a new Crain’s Chicago Business op-ed, AAR President and CEO Ian Jefferies explains how investment and innovation made Chicago the logistics capital of North America—and why smart, performance-based policy is essential as Congress weighs major transportation legislation this year.

AVALANCHE!

BNSF’s “Avalanche Alley” is one of the most challenging winter rail corridors in North America. To keep trains moving safely through this snow-prone stretch in Montana, BNSF uses a proactive avalanche program.

This program combines weather monitoring, on-the-ground inspections, protective snow sheds, and close coordination with experts and public agencies. By managing avalanche risk before it becomes a disruption, BNSF helps protect crews, infrastructure, and critical freight flows during the harshest winter conditions.

Keeping Operations Safely Moving

From late January 2018 into early February 2019, heavy snow, ice, and wind chills plunging to –50°C strained rail operations across northern Illinois and Indiana. Norfolk Southern responded with round-the-clock monitoring and rapid action to keep trains moving.

Track teams conducted “cold patrols” to detect rail contraction and prevent breaks, making temporary repairs and heating rails as needed to maintain alignment. The effort shows how modern winter railroading relies on preparation, continuous inspection, and quick fixes to sustain network operations during extreme cold.

Fun Fact: When It’s So Cold, Railroads Bring the Heat

In extreme cold, freight railroads sometimes do something surprising: they safely set the tracks on fire. As steel rails shrink in freezing temperatures, crews use switch heaters powered by propane or electricity to warm and expand the rail, preventing breaks and keeping trains moving. It’s a carefully managed, time-tested technique that helps railroads maintain service during brutal winter conditions.

BONUS WATCH 👀: Switch Heaters Keep Metra Rolling in Winter Weather

Then & Now: Winter

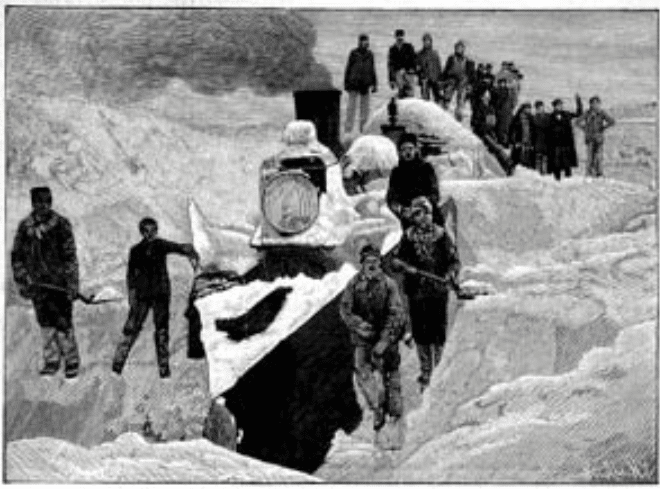

👆 Crews dig out a snow plow after repeated high-speed runs into deep drifts left the locomotive stalled and buried.

In the early 20th century, railroads faced winter like a siege. When blizzards buried tracks in deep drifts, crews relied on steam-powered rotary snow plows with massive spinning blades, often pushed by multiple locomotives just to break through. It was brute force against nature, and major storms could stall entire routes for days as railroads fought to keep supply lines open.

👆 Raymond Lewis, a railroad photographer, captured drone footage in 2023 of Union Pacific’s spreader going over the Upper Cascade Bridge on Donner Pass. Read more from Union Pacific here.

Today, railroads still train crews for winter, but they fight storms with far more capable tools. Modern snow plows are stronger, smarter, and designed to absorb impact while protecting locomotives.

Combined with advanced weather forecasting, network sensors, and shared network data, railroads can deploy powerful equipment where it’s needed most—keeping lines open and traffic moving through winter weather.

Industry Reads

- Trains: Norfolk Southern orders 40 Wabtec ES44AC locomotives

- Progressive Railroading MxV Rail’s international partnerships aim to advance rail research at home and abroad (Premium)

- FreightWaves: Cargo theft remains elevated across U.S. and Mexico as organized crime adapts

- Washington Legal Foundation: A Forceful Railroad Regulation Policy Statement on Preemption Serves the Public Interest

- Washington Examiner: Honoring America’s 250th by building the next generation of freight rail (Opinion)