FREIGHT RAIL HAZMAT KEY FACTS

- Hazmat accident rates are down 80% since 2005.

- Railroads want shippers to fully disclose and label hazmat and share in liability and safety efforts.

- Freight railroads called for tougher tank car safety standards.

Freight railroads safely move large quantities of hazmat critical to our nation’s health and quality of life. This includes fertilizer, ethanol, crude oil and chlorine. However, railroads generally do not own the tank cars they transport. Instead, they are often purchased and maintained by shippers or equipment leasing companies. Railroads, as common carriers, must transport any freight, including hazmat, properly tendered on reasonable terms and conditions.

The U.S. Department of Transportation (DOT) has indicated that railroads remain the safest above-the-ground mode of transportation for hazmat. Therefore, it has supported the decision to continue the enforcement of this common carrier requirement.

Railroads safely move hazmat.

Railroads prioritize safety through prevention, mitigation, and emergency response, continuously improving hazmat operations. As a result, the hazmat accident rate per carload is at its lowest ever—down 80% since 2005. With over 99.99% of hazmat shipments arriving safely, freight rail remains the safest transport method.

Railroads invest heavily in infrastructure and technology to enhance safety across all commodities. Their hazmat safety strategy focuses on three key areas:

- Prevention—avoiding accidents,

- Mitigation—minimizing impact, and

- Emergency Response—training first responders and providing resources like the AskRail app.

Shippers are also key to keeping rail hazmat safe.

Ensuring the safe shipment of hazmat is a shared responsibility between shippers and railroads. Under federal law, shippers are responsible for selecting and securing the package when hazardous materials are put into transportation.

Specifically, shippers are responsible for ensuring the products are loaded in appropriate and approved tank cars. These must bear necessary safety placards. Hazmat shippers are also required to provide railroads with accurate shipment content documentation. They must have a security plan and incident reporting procedures in place in the event of an emergency.

Federal requirements allow the railroad to trust that the shipper has taken all appropriate measures. This trust holds unless a ground-level inspection suggests otherwise. If those requirements are met, railroads are required to move products under their common carrier obligation.

Railroads follow strict transportation regulations.

The transportation of hazmat by rail is subject to rigorous oversight by the Federal Railroad Administration (FRA), the Pipeline and Hazardous Materials Safety Administration (PHMSA), and the Department of Homeland Security (DHS).

Railroads work with these and other local, state, and federal entities to ensure safe train movements. This includes effective tank car designs. Federal law requires rail customers to properly disclose and label hazmat shipments to ensure that appropriate railcars are used. They must assist emergency responders in case of an accident. Freight railroads support asking rail shippers to do their part to protect the safety of rail operations by fully and accurately disclosing and labeling hazmat shipments.

Tank Car Oversight

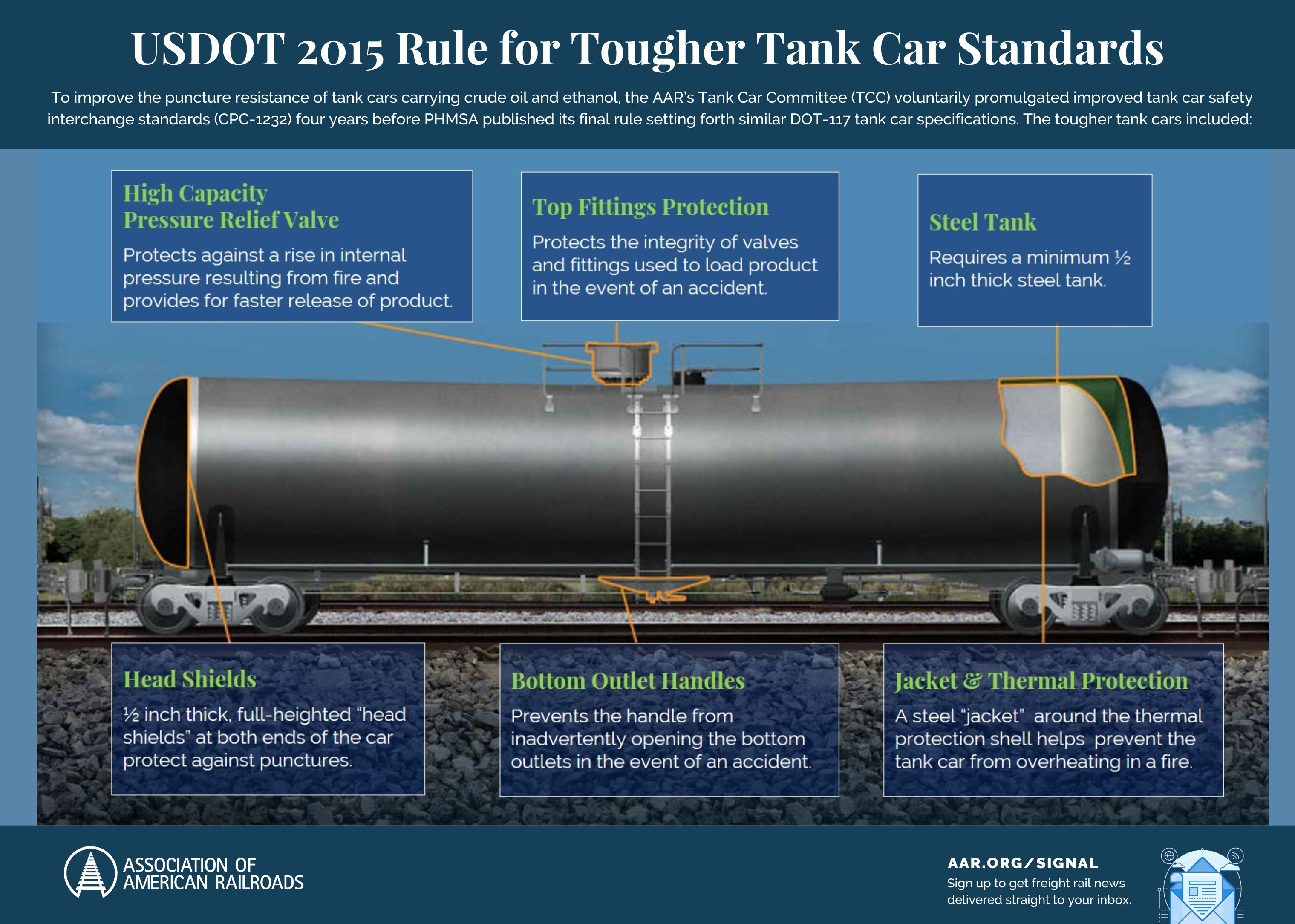

The current oversight system for rail tank cars is multi-faceted. Federal minimum standards are sometimes exceeded by industry best practices. In this system, the DOT, specifically PHMSA, retains regulatory authority over the safety of rail transportation. This includes regulations covering product classification, operating rules, and minimum specifications for tank cars.

Due to its technical expertise in safety-critical functions, DOT has delegated its authority on certain tank car safety matters to the AAR Tank Car Committee (TCC). This includes technical design review. The TCC comprises representatives from the railroads, shippers, and tank car builders and owners. Additionally, representatives from the Federal Railroad Administration, PHMSA, the National Transportation Safety Board, Transport Canada, and the Transportation Safety Board of Canada regularly attend and participate in many of the TCC’s quarterly meetings.

Separate from this delegated authority, the TCC also reviews and sets industry-wide interchange standards for the design and operation of tank cars in North America. This occurs under the voluntary agreement of the rail industry. While these interchange standards can sometimes require the tank car industry to exceed, or more quickly meet, DOT’s regulations, they can never relax DOT’s minimum requirements or degree of oversight.

This system has ensured that today’s tank cars are built with better thermal protection, higher-grade steel, and better valves and fittings. It has improved tank car safety at an otherwise impossible speed through the traditional regulatory process. For example, to improve the puncture resistance of tank cars carrying crude oil and ethanol, the TCC voluntarily promulgated improved tank car safety interchange standards (CPC-1232). This occurred four years before PHMSA published its final rule setting forth similar DOT-117 tank car specifications.